Crecimiento y caracterización de láminas delgadas

Científicos responsables :

Dra. Olga Sánchez (Científica Titular)

Dr. Ignacio Jiménez (Científico Senior)

Dr. Raúl Gago (Científico Titular)

Personal técnico

Dr. Leo Álvarez (Técnico Especializado)

Contacto

@email

+34 913349000 ext. 437381 / 301 / 306

+34 913349078 ( número directo)

Ubicación

Laboratorio 301, 305 y 307

El servicio de Caracterización y Crecimiento de Películas Delgadas está dirigido a la fabricación de películas delgadas y recubrimientos (incluidos materiales bajo demanda) mediante pulverización catódica o evaporación térmica y/o caracterización de capas mediante diversas técnicas como perfilometría, UV-VIS- NIR, mediciones de resistencia de 4 puntas o nanoindentación.

Medidas y equipamiento.

A. Sistemas de deposición de películas delgadas:

• Sistemas de pulverización catódica:

1. Sistema de metalización. Cámara de vacío cilíndrica con una fuente de pulverización de magnetrón circular (3 pulgadas de diámetro) para el crecimiento de metales en película delgada (Al, Cu, Si, Ti, Ag…) sobre sustratos planos.

2. Sistema de magnetrón reactivo. Cámara de vacío cilíndrica con hasta 3 fuentes de magnetrón planas circulares (3 de diámetro), que funcionan simultáneamente para la deposición de óxidos metálicos, nitruros y de oxinitruros en capa delgada. Fuentes eléctricas de DC y RF.

Tamaño máximo de muestras para ambos sistemas: 4x4 cm.

• Sistema IBAD (evaporación térmica asistida por haz de iones).

Esta técnica permite la evaporación de diferentes elementos o compuestos con el bombardeo simultaneo de electrones e iones generados a partir de determinados gases (nitrógeno o gases nobles). El sistema utilizado consta de una cámara de vacío en cuyo interior se encuentran dos evaporadores de haz de electrones y un cañón de iones Kauffman.

B. Técnicas de caracterización:

1- Perfilómetro de contacto, marca Veeco mod. Dektak 150

El perfilómetro es una herramienta avanzada de medición de altura de escalón de película delgada y gruesa capaz de medir escalones por debajo de 100 Å. También mide muestras de hasta seis pulgadas de dimensión y hasta cuatro pulgadas de espesor. El Dektak 150 permite perfilar la topografía y la ondulación de la superficie, así como medir la rugosidad de la superficie en el rango nanométrico. El sistema proporciona una repetitividad de altura de paso de 0,6 nm. En la configuración estándar, la fuerza de la punta programable por el usuario de 1 a 15 mg permite perfilar en superficies blandas o duras.

2- Perfilómetro óptico Profilm3D.

El perfilómetro óptico es un sistema interferométrico de luz blanca (WLI), que incorpora por defecto una platina motorizada de 10x10 cm, escaneo piezoeléctrico de 500 µm y está equipado con objetivos de 20x y 50x. El sistema permite mediciones de campo amplio sin contacto utilizando diferentes modos estándar: WLI, PSI, WLI/PSI compuesto e imágenes en color verdadero. Los datos resultantes capturados son un mapa 3D de la superficie de la muestra. Profilm3D también calcula los 47 parámetros de rugosidad estándar ASME/EUR/ISO.

3- Espectrofotómetro Shimadzu UV-VIS-NIR SolidSpec-3700/3700DUV.

Rango de longitud de onda medible: 190-3300 nm. El espectrofotómetro tiene tres detectores que cubren el rango desde el ultravioleta hasta el infrarrojo cercano. SolidSpec permite mediciones en el rango de 190 nm a 2600 nm con una esfera integradora (con resina que tiene características altamente reflectantes en la región ultravioleta profunda como material interior) y el rango de 190 nm a 3300 nm montando la detección directa opcional Unidad DUV (con esta unidad adicional ahora se puede medir el amplio rango desde el ultravioleta profundo hasta el infrarrojo cercano).

Dimensiones de la muestra: Muestras rectangulares donde cada lado mide entre 50 y 310 mm. Espesor inferior a 40 mm.

El método de medición utilizado para muestras sólidas ser medición de transmisión, en la que se mide la luz que pasa a través de la muestra, o medición de reflexión, en la que se mide la luz reflejada en la muestra. Además, la medición de transmisión y la medición de reflexión se pueden subdividir en varios tipos: mediciones directas, totales y difusas.

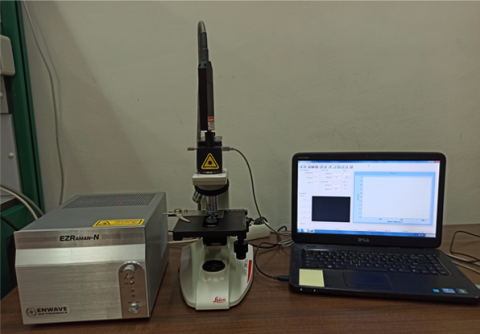

4 - Raman portátil confocal EZRAman-N NWAVE Optronics.

Este equipo con láser verde de estado sólido (532 nm) y espectrómetro CCD refrigerado termoeléctrico con microscopio Leica BME (objetivos 4× 10× y 40×) se utiliza para la caracterización de muestras de carbono amorfo hidrogenado, nanotubos de carbono, capas de grafeno, capas de nitruro de boro y capas de óxido metálico, entre otras.

Potencia del láser: 0-50 mW.

Rango de longitud de onda: 100-3300 cm-1.

Resolución espectral media: 7 cm-1.

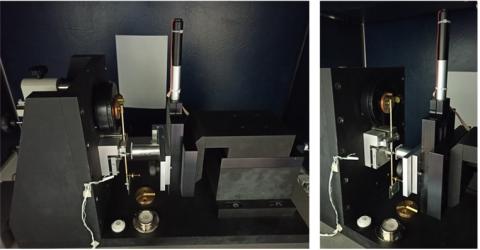

5- Nanoindentador, mod. NanoTest P1, de MicroMaterials, e indentador Berkovich.

El sistema tiene hasta 3 módulos separados (indentación, escaneo e impacto). El NanoTest mide el movimiento de una sonda de diamante en contacto con una superficie. Durante toda la prueba se registran la fuerza, el desplazamiento y el tiempo. El nanoindentador permite obtener curvas carga-descarga con cargas de hasta 500 mN, la dureza y módulo de Young de capas delgadas con espesores del orden de 1 micra.

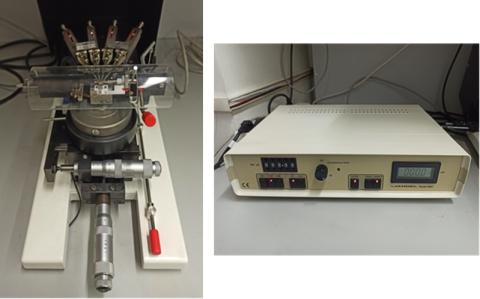

6 - Medidas de resistividad con medidor de 4 puntas.

Se utilizan con cuatro sondas para obtener la resistividad/resistencia laminar de películas delgadas sobre sustratos planos con espesor conocido. Curvas I-V. Durante la operación con cuatro sondas, las cuatro agujas suben y bajan normalmente. Un amortiguador de aire controla la velocidad de descenso de las agujas y, por lo tanto, ofrece condiciones de contacto uniformes de una medición.

Carga: 0-100 g aplicada mediante medidores de tensión individuales ajustables.

Dimensiones de la muestra: Solo obleas, el diámetro máximo normal es 76 mm.

Fuente de corriente: corriente continua de 10 nanoamperios a 999,990 nA (o 0,99999 mA) y 100 nanoamperios a 9.999.900 nA (o 9,9999 mA (rango x10)). Aplicación directa con un interruptor de botón de 5 décadas.

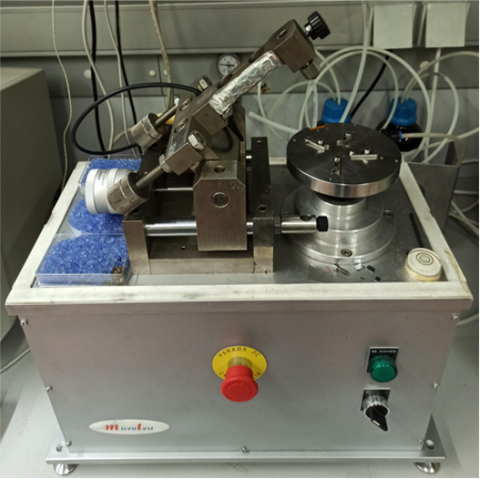

7 – Tribómetro ” pin-on disk”.

Ensayos tribológicos para evaluar tanto la fricción como el desgaste entre dos superficies en contacto. Consiste en un disco estacionario y un pasador o perno que se desliza o gira sobre la superficie del disco. En esta prueba, se aplica una carga conocida al pasador y se mide la fuerza de fricción generada entre el pasador y el disco durante el deslizamiento. Adicionalmente se registra el desgaste del material tanto del pasador como del disco. Para realizar estos ensayos ofrecemos en nuestro servicio diferentes tipos de pernos (alúmina, acero y/o carburo de tungsteno), dependiendo de la dureza del sustrato.

ICMM

Sor Juana Ines de la Cruz, 3

Cantoblanco, 28049

Madrid, España

Teléfono: (+34) 91 334 90 00

Email: @email

Oficina de Comunicación/Prensa: @email

Acknowledge the Severo Ochoa Centres of Excellence program through Grant CEX2024-001445-S/ financiado por MICIU/AEI / 10.13039/501100011033

Contacto | Accesibilidad | Aviso legal | Política de Cookies | Protección de datos