Textural Characterization

Scientist in Charge:

Dr. Miguel A. Camblor (Research Professor)

Dr. Pilar Aranda (Senior Researcher)

Dr. Javier Pérez Carvajal (Research Associate)

Technicians

Dr. Elena López Elvira (Research Assistance)

Contact

+34 917166507

+34 913349000 Ext. 437375, 437126, 437204

Location

Lab S13 (basement)

ICMM-CSIC, C/ Sor Juana Inés de la Cruz 3, 28049 Madrid, España

Physical gas adsorption techniques and mercury porosimetry allow the characterisation of porous solids texture. Gas adsorption/desorption curves at constant temperature (isotherm) allow the surface area and pore size distribution determination among others in micro-mesoporous solids . High-pressure mercury intrusion allow the determination of the porosity of the materials showing accessible pores in the range of 1 micrometer to 1 mm.

Measurements

- Determination of the specific surface area from the adsorption-desorption isotherm by nitrogen physisorption at 77 K applying the BET method to the isotherm obtained. Standard degassing conditions are 120 ºC during 24 hours (indicate if other conditions are required in the application form).

- Obtaining the adsorption-desorption isotherm by physisorption of argon at 87 K. Standard degassing conditions are 120 ºC during 24 hours (indicate if other conditions are required in the application form).

- Determining the specific surface area of powder by one-point method. The samples are degassed at 150ºC for 30 minutes (indicate if other conditions are required in the application form).

- Analysis of the distribution and size of pore, in porous solids through the intrusion of mercury, from 4 to 940 microns as standard, with the possibility of downloading the software for more advanced operations. The measurement is carried out without previous degassing to determine mercury intrusion as a function of the applied pressure from ambient pressure and temperature.

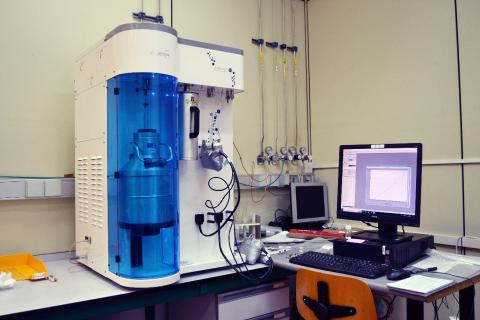

Equipment:

The textural analysis laboratory has the following equipments:

• Micromeritics Flowsorb 2300.

• Autosorb iQ from Quantachrome Instruments.

• Poremaster Series Quantachrome Instruments.

Measurements of reference samples are carried out periodically on all equipment to check their correct operation.

The Quantachrome iQsorb gas adsorption equipment has two simultaneous measurement ports and four automated thermal activation ports for the determination of specific surface, micro- and mesopores, as well as possible physical-chemical derivatives of the measurement through numerical analysis that are accessible to the user through the provided software.

The Micromeritics Flowsorb 2300 equipment allows rapid determination by flow of the specific surface of porous solids by the 1-point method.

The Poremaster equipment allows mercury intrusion-extrusion into the accessible pores of different solids, allowing the calculation of the pore distribution in the range of 4 to 940 microns.

Allowed samples

These analyses are carried out on materials of different chemical nature, including carbons, zeolites, silicates and clay minerals, as well as various hybrid materials, metal oxide nanoparticles and metal-organic and covalent organic structures, where the determination of porosity is a critical parameter.

On the other hand, the textural determination of shaped solids is more common in mercury porosimetry. Among other types of samples, polymeric films, pellets and foams of different nature can be analyzed, including carbonaceous materials and their composites.

The samples provided should be porous solids in powder form with a minimum mass of 100 mg. For high porosity materials (MOF or COF) the minimum quantity is 50 mg.

The samples are received by mail or at the ICMM through a sample tray with the attention of the ICMM support staff, while digitally it is required to send a detailed analysis request through the LIMS platform that includes the chemical nature of the sample, its thermal stability, its toxicity and environmental stability, as well as any peculiarity in the handling of the sample.

The results obtained are digitally transferred to the user through the LIMS platform.

Samples can be picked up in the laboratory for a period of 3 months, with samples not claimed within that period being eliminated.

Instituto de Ciencia de Materiales de Madrid (ICMM)

Sor Juana Ines de la Cruz, 3

Cantoblanco, 28049

Madrid, España

Telephone: (+34) 91 334 90 00

Email: @email

Communication Office: @email

Acknowledge the Severo Ochoa Centres of Excellence program through Grant CEX2024-001445-S/ financiado por MICIU/AEI / 10.13039/501100011033

Contacto | Accesibilidad | Aviso legal | Política de Cookies | Protección de datos