Researchers reach a new material capable of producing green hydrogen with ten times less iridium

This electrocatalyst will help to reduce the cost of producing sustainable energy from renewable sources.

International research groups, including teams from the Institute of Catalysis and Petrochemistry (ICP) and the Materials Science Institute of Madrid (ICMM), both part of the Spanish National Research Council (CSIC), have achieved a compound capable of generating green hydrogen using ten times less Iridium, an extremely scarce and expensive transition metal. The results have just been published in the journal Advanced Energy Materials.

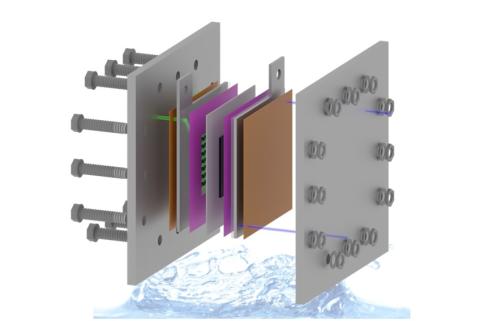

Green hydrogen is obtained through water electrolysis using renewable energy sources, and it is expected to facilitate the transition to a decarbonized society. To produce this hydrogen, electrolyzers are needed, such as the so-called Proton Exchange Membrane (PEM) electrolyzers, which "work very well, are efficient, but are very expensive due to the materials they use," explains Sergio Rojas, a researcher at the ICP and one of the authors of the study. One of these materials is Iridium, "which is not only expensive but also one of the scarcest and least distributed materials," he adds.

Currently, one troy ounce (a unit of measurement used for precious metals equivalent to 32.15 grams) costs $4,600, according to Johnson Matthey, a leading company in the sector. For this reason, these teams have designed a metallic oxide, a compound (catalyst) with 10 times less iridium compared to the one used commercially (from 2 milligrams per square centimeter to 0.2), while achieving the same performance.

"We have reduced the cost of the catalyst by a factor of ten," says José Antonio Alonso, a researcher at the ICMM and also an author of the study. He highlights how this study "demonstrates the importance of fundamental research as a preliminary step to applied research: we obtained this compound ten years ago, but until now, we had not found an application for it."

María Retuerto, a scientist at the ICP and also an author of the study, adds, "This opens the door to other similar and scalable materials." The scalability of this specific compound is complex because it requires a rare machine located at the ICMM, which uses a furnace with 200 bars of oxygen pressure, according to Alonso. However, the researcher is optimistic: "These iridium-based materials start from a starting compound whose surface is modified during the reaction; what we are seeing now is that maybe we don't need to have exactly that starting compound. We can have something very similar, and in the end, the restructuring of the surface gives us the same catalytic activity."

"When we talk about scaling, we mean producing several tons, producing on a massive scale," recalls Rojas, who nevertheless highlights this compound as "a precursor to a catalyst" that is enabling the development of other compounds. Several companies have already shown interest, such as Johnson Matthey.

The process by which this compound and its derivatives work have been explained by the same teams in another paper published in Nature Communications at the end of 2022, where they already defended what they have now demonstrated: that it was indeed possible to reduce the level of Iridium in the catalysts used in PEM electrolysis. "Although alkaline electrolysis is the most developed technique, PEM technology is very fast and capable of producing large amounts of high-purity hydrogen. For now, it requires iridium at its anode, and that is the main obstacle to introducing the technology on a larger scale in the market," concludes Retuerto.

-- Info paper: Jorge Torrero, Tobias Morawietz, Daniel García Sanchez, Dmitry Galyamin, Maria Retuerto, Vlad Martin-Diaconescu, Sergio Rojas, José Antonio Alonso, Aldo Saul Gago, Kaspar Andreas Friedrich. High Performance and Durable Anode with 10-Fold Reduction of Iridium Loading for Proton Exchange Membrane Water Electrolysis. Advanced Energy Materials. DOI: 10.1002/aenm.202204169

-- Ángela R. Bonachera - Unidad de Comunicación del ICMM/CSIC --

-- Picture: Dmitry Galyamin --

Instituto de Ciencia de Materiales de Madrid (ICMM)

Sor Juana Ines de la Cruz, 3

Cantoblanco, 28049

Madrid, España

Telephone: (+34) 91 334 90 00

Email: @email

Communication Office: @email

Acknowledge the Severo Ochoa Centres of Excellence program through Grant CEX2024-001445-S/ financiado por MICIU/AEI / 10.13039/501100011033

Contacto | Accesibilidad | Aviso legal | Política de Cookies | Protección de datos